1. Products utilized in combustion systems and boilers

The combustion system is designed to utilize heat for the purpose of fuel combustion. It comprises several critical main components, including:

• Furnaces: The furnace plays a pivotal role in the combustion of fuel to generate hot gases essential for the production process. To maximize the production of heat energy, it is imperative to employ an efficient and fuel-specific stove.

• Boilers: This is a crucial apparatus employed to generate steam for heating within industrial production processes. This includes utilizing steam pressure to propel a steam turbine to generate electrical energy. Products utilized in combustion systems include.

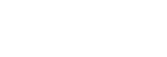

Soot Blower: for cleaning steam boiler pipes

This equipment is designed for the removal of soot and various ashes that accumulate within steam boiler pipes during fuel combustion. It is affixed to the exterior of the boiler and features an extended pipe for effectively dislodging insulating soot, thereby enhancing combustion efficiency and preventing scale buildup within the boiler. The primary sectors that extensively utilize this equipment are the energy and petrochemical industries.

Heating Element: for facilitating heat exchange within the combustion system

This device serves the purpose of heat transfer by utilizing two fluids to absorb heat from a hotter source, with the primary objective of elevating heat energy for electricity production.

2. Products utilized in waste and exhaust management systems

The waste and exhaust management system is a process designed to filter and purify various substances generated by the combustion system, with the primary aim of reducing greenhouse gas emissions before they are released into the environment. Hence, the exhaust gases undergo a complex purification process that involves removing nitrogen oxides, capturing mercury vapor, filtering out dust, and eliminating sulfur dioxide gas. After this extensive treatment, the purified exhaust gas is then released through the chimney.

In dealing with waste materials generated from fuel combustion, heavy fuel ash is transported and deposited in an ash dump for repurposing. This ash can be utilized for various other purposes. Here are some examples of products that make use of waste.

Electrostatic Precipitator: filtration devices utilize static electricity to remove fine dust

This exceptionally effective device is designed to capture suspended particles or dust from high-temperature combustion processes. Its operational principle relies on the creation of an electrostatic field, effectively separating dust particles and oil vapors from the exhaust gas.

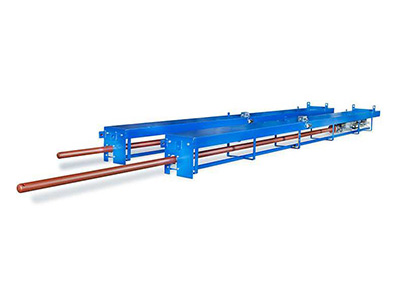

Industrial Fans: for ventilation in manufacturing systems

A sizable industrial fan that either draws in air or facilitates air circulation in various industrial applications, including the steel industry, power plants, cement production, metallurgical plants, petrochemical processes, waste incineration, drying, evaporation, and dust extraction.

Steel Grinding Balls

It is a compact sphere, measuring approximately 2.5 inches in diameter, employed for grinding raw materials by utilizing the principle of rotational grinding. For instance, it is effective in grinding limestone into a fine powder.

Rubber Liners

Anti-shock rubber components installed within the grinder alongside steel balls serve to protect the grinder from excessive wear and tear.

Mist Eliminator: for eliminating fine droplets

This device functions as a filter, effectively separating water droplets to minimize water loss during the production process. It reduces the overall water wastage as the filtered water droplets are collected and returned to the production process.

Slurry Pump: for moving mixtures of liquid and solids

This device is employed to transport solutions containing solid particles, like limestone water, and is specifically designed with materials that can withstand the wear and tear caused by the liquid's pH.

Propeller Stirrer

This is a device used for agitating liquids within water tanks to prevent the settling of precipitates.

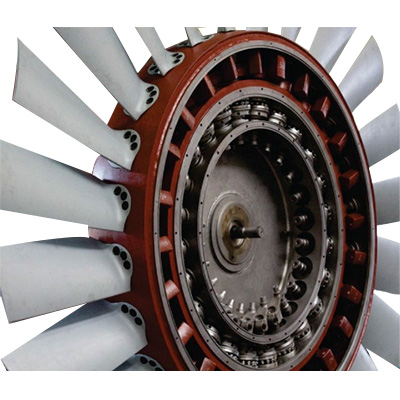

Dewatering Systems: for sediment filtration

A belt system equipped with a solution filter cloth is employed to separate solids from liquids. The solids that pass through the conveyor are considered waste but can be repurposed for other uses. Meanwhile, the liquid portion, primarily water, is recycled and reused in the production process.

3. Equipment used in the cooling systems

The cooling system, located within the cooling tower, functions to lower the temperature of hot water, transforming it into cold water. This is achieved by facilitating direct contact between air and water, leading to a decrease in water temperature. Subsequently, the cooled circulating water is returned for reuse within the factory or in various systems, such as pump cooling, steam turbine cooling, and heat exchange. Here are some examples of products used in cooling systems.

Fill Pack: a cooling component inside the cooling towers

The mist distribution panel within the cooling tower operates on the principle that water droplets adhering to it will experience a decrease in temperature.